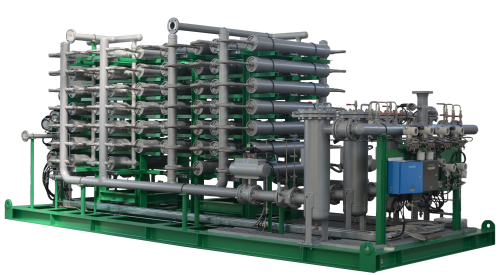

Nitrogen Generator

Membrane type and PSA/CMS (pressure swing adsorption/carbon molecular sieves) type, providing N2 purity up to 99,99%. Nitrogen flow rate and purity on Customers demand

Technical details

The nitrogen is one of the most readily available and economical inert gases. It is used to avoid combustion, corrosion and product spoilage. Many industries use nitrogen for their manufacturing processes, including food and beverage, electronics, petrochemicals, pharmaceutical and metal operations.

On-site nitrogen generation has many benefit:

• Lower operating costs;

• Simplify business processes;

• Reduction of waste;

• Avoid safety and footprint issues associated with storing nitrogen

• Use N2 purity tailored from 97% to 99.999%

MEMBRANE MODULES

Pressurized air is fed into the hollow fibres. The permeation rates of water vapour, CO2, and oxygen contained in the air stream are faster than nitrogen and other residual gases and will rapidly diffuse through the fibre walls. The slower diffused nitrogen molecules remain in the fibre bore and are collected as gaseous nitrogen while the other gaseous elements will be discharged in the atmosphere.

MEMBRANE SELECTION

Membrane are composed of a bundle of synthetic hollow fibres compressed and inserted inside an aluminium or stainless steel casing.

The selected MEMBRANE use special hollow fibres that grant an high selectivity performance in term of high nitrogen product recovery, with low feed air consumption. They are suitable for heavy duty 24 hours/day work, and are capable of providing nitrogen in continuous service at the specified purity, flow rate and pressure.

OXYGEN ANALYZER A N D DIVERTING VALVE

Low purity nitrogen stream will be analyzed in continuous from installed O2 analyzer. A signal repeater will send their readings to UCP. The management of the signals will be programmed by the logic.

The oxygen analyzer will act by means of PLC programming, on an automatic valve installed downstream the analyzer that will deviate the nitrogen flow in case the purity shouldn’t be the requested one. This regulation is in compliance with request automatic change-over the generation trains.

DUE GI Srl di cattani giuseppe & c.

Corso Italia 570, Località Mirabello – 44043 Terre del Reno (FE) Tel. 0532.847812 – Fax 0532.358035